Energy Connections Canada recently welcomed Grey Owl Engineering as a new member, and this week we are introducing them and their exciting work in pipeline leak detection.

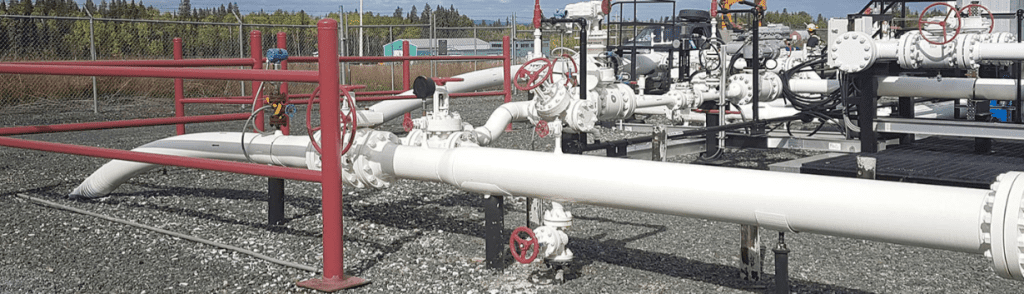

Grey Owl is a full service EPCM business located in Calgary, Alberta. In 2015, they opened a new business unit called Grey Owl Leak Detection (GOLD), aimed at offering leak detection services to the upstream (exploration, drilling and extraction) and midstream (storage and transportation) oil and gas sectors. GOLD specializes in providing leak detection programs and systems, leak detection training and risk management.

GOLD is unique in having created a hybrid leak detection system that combines both a model-based approach and a data-based approach. In other words, it combines theoretical computations defined by the pipeline system and its operating conditions with data generated by sensors such as pressure transmitters, flow meters, temperature gauges and ultrasonic meters.

We spoke with Dr. Stephen Ramsay, senior leak detection specialist at Grey Owl to learn more about their service offerings.

“This hybrid approach allows us to use a description of the physical system and incorporate machine learning to analyze patterns and identify pipeline leaks faster and more accurately,” said Ramsay. “Advanced analytics and algorithms improve our ability to understand the ‘how’, ‘when’ and ‘what’ about leaks under any conditions.”

Being able to detect leaks sooner can help minimize the environmental and financial impacts of the leak.

“We entered into this space because we identified a gap,” said Ramsay. “Transmission pipeline companies tend to have sophisticated leak detection capabilities, but of the 900 or so companies that own pipelines, very few of them are actually pipeline companies – they’re oil and gas producers who use pipelines as part of their operation.”

One of the challenges identified by GOLD, particularly for upstream companies, is that their SCADA (Supervisory Control and Data Acquisition) systems, which monitor, gather and analyze data, do not have the computing capabilities required for sophisticated, fit-for-purpose computational leak detection systems. GOLD is developing an edge and cloud-based computing system to allow for their algorithms to be deployed in the upstream sector.

“The solution has the potential to bring robust, cost-effective computational leak detection systems to an industry space where these systems are typically not deployed due to economic constraints,” said Ramsay.

The technology is currently at the field-testing stage, having passed the proof of concept in a simulated test environment.

In an industry where innovation and technology are paramount in allowing us to reach our safety and sustainability goals, the work of Energy Connections Canada members, such as GOLD is helping us all in our quest for consistent improvement.