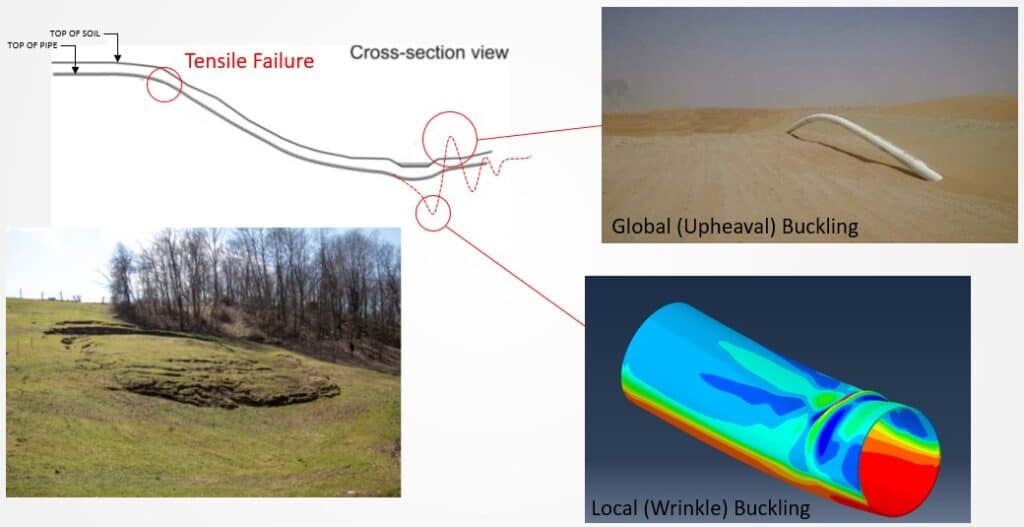

Slope movement and landslides pose a significant risk to pipeline integrity. As such, pipeline operators use inline inspections (ILIs), strain gauging, fibre optics and other techniques to monitor slopes and the pipelines they affect.

Energy Connections Canada member Stress Engineering Services Canada has developed a predictive analysis model that takes the data from these monitoring tools and is able to more accurately predict when incidents may occur so that they can be mitigated before they happen.

We spoke with Kenny Farrow, Principal at Stress Engineering Services Canada, about how predictive analysis can help proactively prevent geotechnical-related pipeline failures.

“Some of the common geohazards affecting pipelines include landslides and slope instability, settlement, erosion and fault movement,” said Farrow. “Our clients come to us with inline inspection data, historical information on ground movement and, in some instances, fibre optic data. From that data, we are able to predict the future life of the pipeline, and specifically, when it will be necessary to repair or replace the pipeline, or to remediate the slope.”

A complex combination of data

Stress Engineering Services Canada is able to work with whatever data is available. At the very least, their clients will have ILI data, and they might also have historical information on how the pipeline has been moving on the slope, ground movement measurements and weather data. The best case is when the at-risk section of pipeline has been fitted with fibre optics, which provides continuous and more complete data.

The advantages of fibre optics

Farrow explained that fibre optics are unique in providing continuous monitoring (over time and space), and that other technologies each have their limitations. Strain gauges are very location-specific (snapshot in space) and could potentially miss the critical location in the pipeline; they can also be negatively impacted by water. Slope inclinometers are able to measure slope movement but they only measure in one specific location, and they eventually need to be replaced when the slope moves excessively. Even inline inspections are only conducted periodically (snapshot in time).

Continuous Refinements

“Modelling makes a lot of assumptions,” said Farrow, “particularly for the soil, so we are continuously refining the model. Looking back comparing predictions with actual events allows us to fine-tune our assumptions based on new information.”

Finite element analysis and modelling is helping pipeline operators ensure the integrity of their pipelines and proactively protect against incidents. For more information on fibre optics providing the data, read ‘High fidelity fibre optic sensing is the newest tool in early detection of landslides’.