Industry-leading technology supporting pipeline integrity

The 2021 CEPA Foundation Award for Quality went to T.D. Williamson for their recent enhancement to the gouge classifier, leveraging their multiple dataset (MDS) platform and their outstanding work in pipeline integrity.

T.D. Williamson offers industry-leading services in pipeline pigging, threat assessment, intervention and isolation to oil and gas companies across the globe. Their sophisticated inline inspection (ILI) technologies are able to accurately identify wrinkle dents, hard spots and dents including complex mechanical damage in pipelines.

The MDS platform combines the data collected from multiple inline inspection technologies on a single inspection device (or smart pig) and, leveraging the most recent work, is able to assess whether an anomaly is a dent that has associated metal loss or a gouge.

To learn why that’s important, we spoke with Matthew Romney, senior product manager at T.D. Williamson.

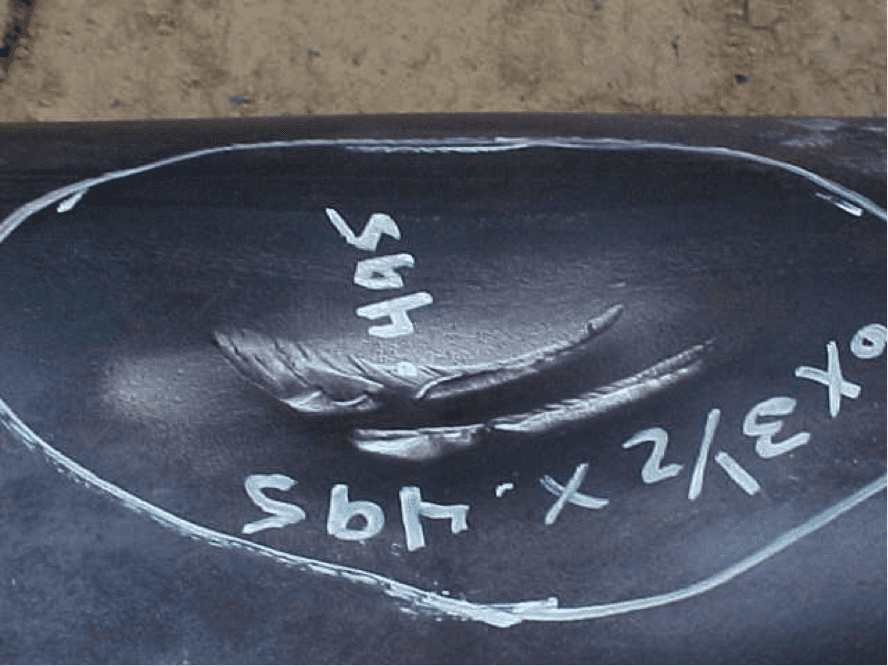

“The question of whether an anomaly is a gouge or a dent with associated metal loss has been a problem in the industry for quite some time,” said Romney. “If you get a dent in a pipeline there will typically be some damage to the coating, and potentially some corrosion. Corrosion will often have a consistent rate of growth, so once it’s identified, it can be assessed, monitored and a mitigation timeline established. With a gouge, such as when a pipeline is struck by digging equipment, there has been some localized work hardening associated with the loss of metal. As a result, the pipeline is more susceptible to cracking.”

The risks associated with a gouge can be more significant than those associated with a dent because the outcome, and the timeline, is harder to anticipate. That’s why it has been a priority for the data science team at T.D. Williamson to produce a classification tool that would enable them to accurately identify gouges.

The MDS platform collects data from six technologies, including axial magnetic flux leakage (MFL), helical MFL, low-field MFL, geometry and mapping; and is able to correctly identify about 90 percent of gouges located within dents. While the MDS platform has been commercially available for more than a decade, the gouge classifier was recently developed as a result of data collected from pipeline operators. Leveraging this data, TDW collected enough data to move from Research and Development into a fully-fledged commercial offering with published performance specifications.

Once the gouge or corrosion has been identified and correctly classified, a validated depth sizing model can be used to provide information on depth.

“This is an industry-leading technology,” said Romney, “and the culmination of many years of work. Our ability to detect, classify and size gouging found within a dent is a leap forward in pipeline safety.”

This is just one of the amazing technologies and innovations that we learned about during the 2021 CEPA Foundation Quality Summit. Stay tuned as we share more of the advances that are making Canada’s pipelines safer and more sustainable.